Building a great build it's not just about buying things off the shelf, doing nice designs, looking for materials and putting it all together in a fabulous package. It’s more a question of going above and beyond. The clients that we work with have come to expect that we go the extra mile and do what no one else does. We don’t just do classic car restorations, we don’t just build nice cars, we build something as a truly unique piece of art.

Case in point, the 1985 Range Rover Classic that we’re helping restore for a client. This is a family heirloom that he learned to drive way back in the midst of the 1980s and he wanted it brought back exactly the way it was before. Maybe with a couple of nice little upgrades, some touches here and there that will make it much more than it used to be, while still preserving the integrity of the original design that he so fondly remembered from his childhood.

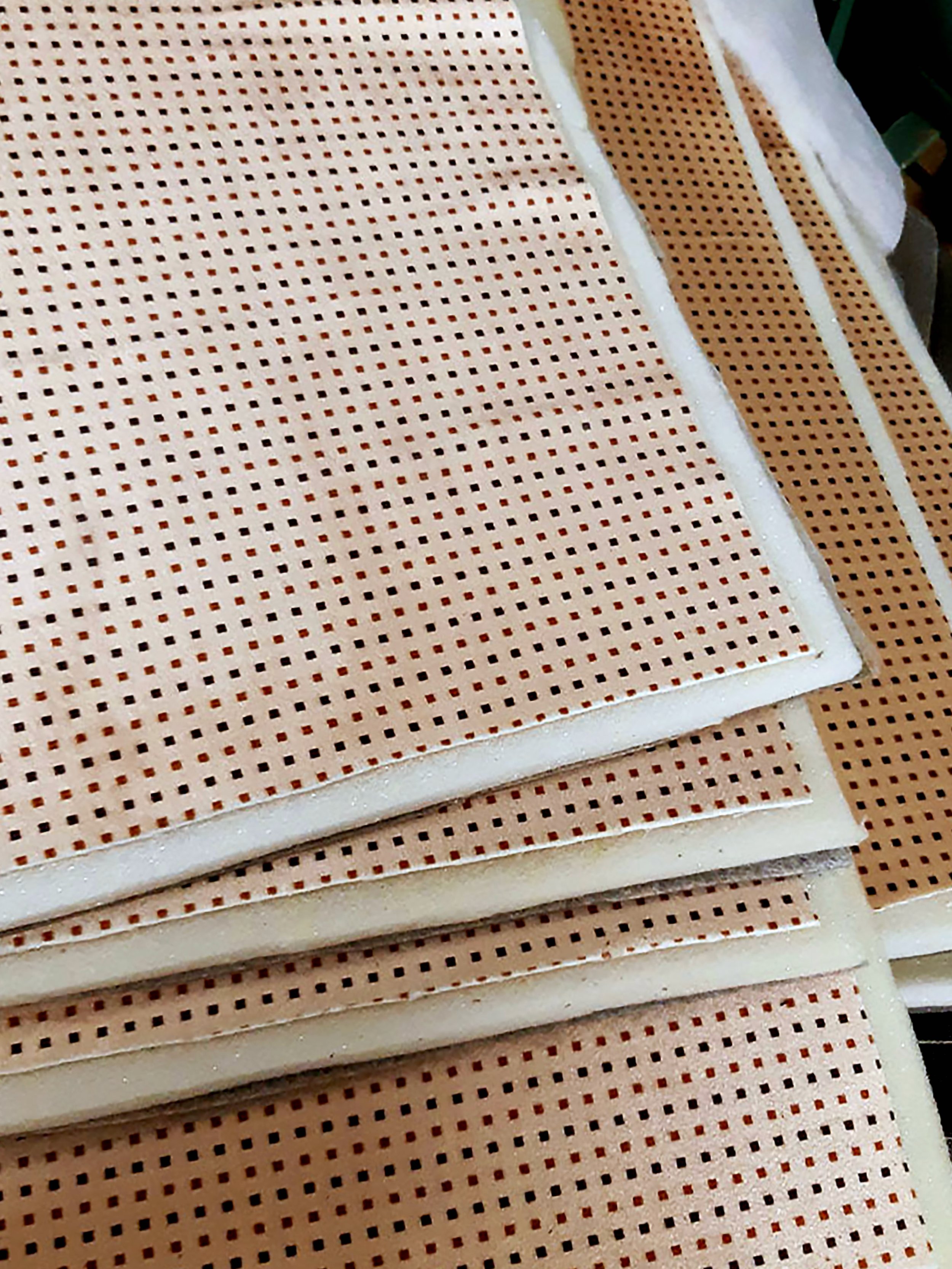

The car had a very specific interior pattern that only came with a French Range Rover from that era. Unfortunately, as we started looking around with our upholstery experts to custom make the interior by hand, and make it exactly like it was before - with everything from the Palomino PVC sidings to the seat patterns and the carpets - there was nowhere we could get a hold of that unique pattern.

We told the client that this was a tough one and asked him what we could do instead to make the project move forward. Maybe we could look for some other alternatives? We could use leather and a new design? No! He insisted: I want it exactly like the way it was before; just make it happen! Well, fortunately for him, that’s our business, we make things happen like nobody else can!

But, how to make it happen when we couldn’t just get something off the shelf; we couldn’t just incorporate it into design? Well, this is where we come in and stand out!

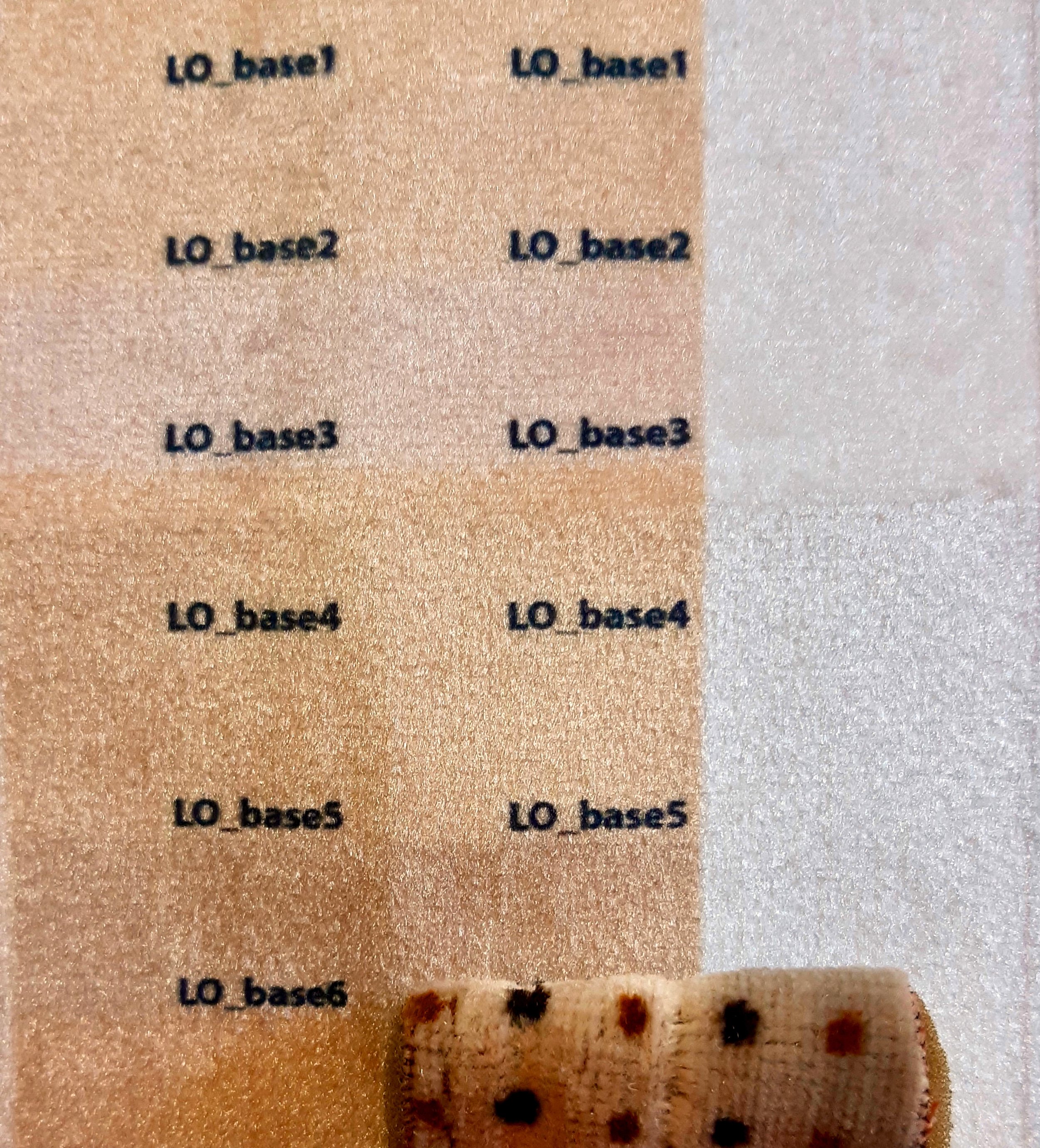

We started by looking at photos of the old designs as well as at old tattered and torn materials that we still had left in the car from its glorious days. With a detailed focus mind we custom designed the pattern in photoshop and came up with the exact right colorations, as well as the different sizing and dimensions of it. After that we worked with a dye sublimation specialist company to make special runs, just for us, of the fabric with the right colors.

This was a hindered process though, as it is not easy to just get all the patterns and colors right as the light and material changes, it all reflects light in different ways, and also the color changes depending on the way the dye absorbs in the fabric itself. But after several runs to get it perfect, and some frustrating conversations about perfection with the producers, we finally got into a place where we had an identical match to the original in high grade fabric material that could withstand all the wear and tear that a car is used to. We looked for the Martindale’s score to make this really stand out as a top notch material, as well as looking gorgeous.

Finally we got the fabric shipped, after a long and lengthening process, to where our upholsterers could incorporate it into the seats, and make the interior look better than the original, although maintaining the pattern, color and design as it was in 1985.

And as always, we made it happen!